Don’t Overlook Preparation in Material Handling

At first glance, your task seems clear. You’ll need to move a large shipment of oddly sized raw materials from the unloading bay to the shop floor. And you’ll need to do it within a limited time frame; some of the materials are perishable, some are needed in various processing areas immediately, and some must be moved and stored to make way for new items that will quickly fill the vacated space.

Simple, right? Not exactly. On closer inspection, this task may be more complex than it seems, especially if your direct reports—not you—will be the ones doing the heavy lifting. In that case, you’ll not only need to formulate a plan of efficient action, you’ll also have to communicate your plans clearly and safely to teams that may not benefit from your level of experience. Here are a few things to keep in mind during your next steps.

Assess the environment for risks.

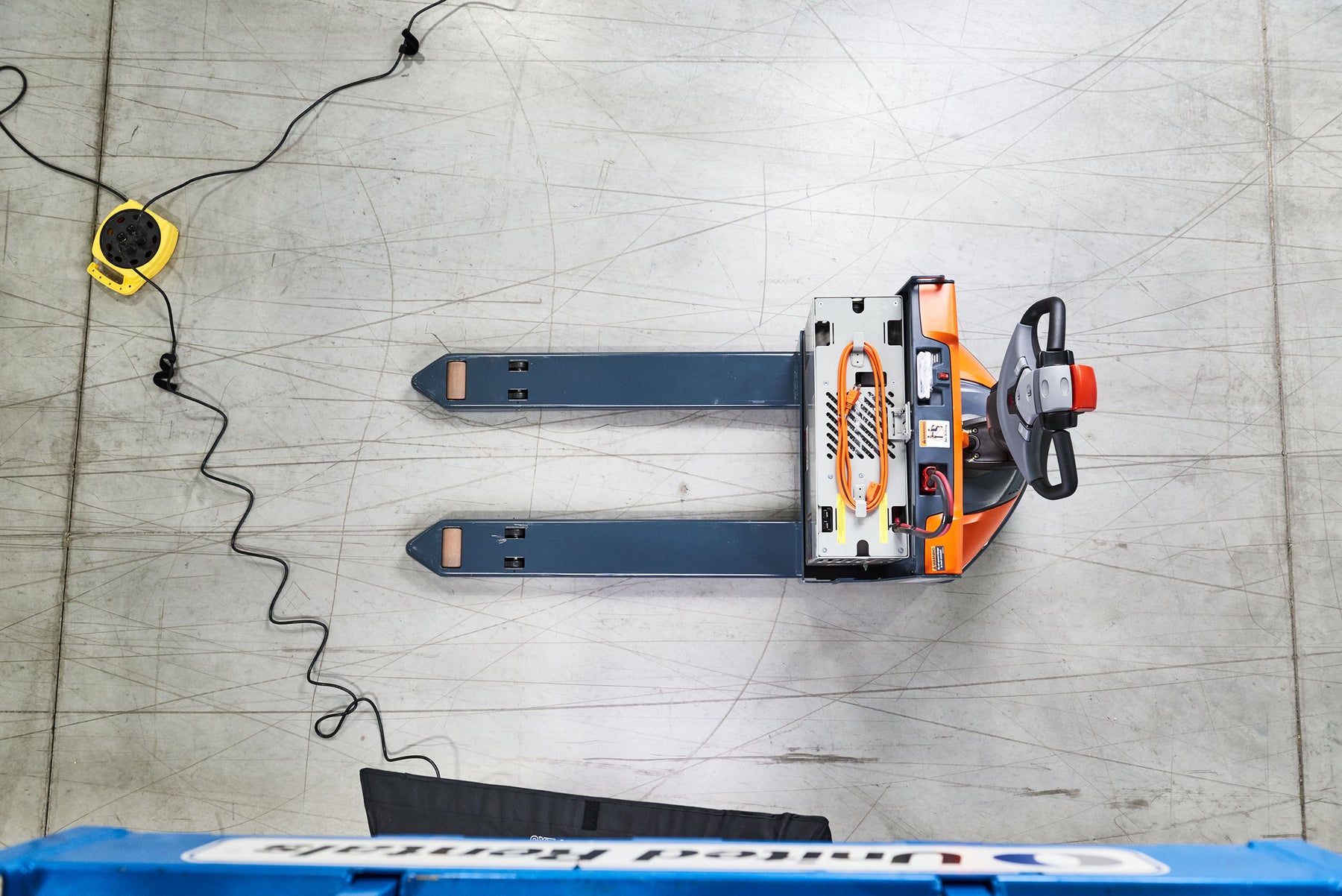

Before you lift one item or move one box, look around. Check the integrity of the floors (are they wet or dry?), look for obstacles (is the path clear?) and look for visibility issues, blind corners and other concerns that might create problems once the work is underway. Are your lift trucks fully and safely fueled? Are your landing areas safe? Are pedestrians present? After risks are addressed, feel free to take action.

Assess the load (or loads).

How many trips do you imagine the entire task will take? Gain a full understanding of each load and its requirements. For example, some objects may be lighter in weight, but awkwardly sized, which will require only a small load per trip. Some may be heavier but easier to load and stack. Get a broad overview and factor your overview into the length of time you have available for the entire task.

Prioritize.

Which items will need to move first? Which can stay until the final stages of the process? Which will need to arrive first in the destination area? Which can lag? Come up with a clear and meaningful order for each action or category of actions; don’t get caught finishing half of one task and half of another before rushing to start (but not finish) a third. Your motions and decisions should be methodical and consistent.

Gain confirmation.

Get a verbal or written confirmation of your instructions from your teams before you walk away and leave them to the task. Otherwise you may return an hour later to a situation of total chaos, or to an hour of incorrect work that needs to be undone before the primary task can be properly started (or restarted). Communication is essential in the materials handling field.